Ib Leeg Ntsa Homogenizing Tank

KHOOM Npe

Cov roj ntsha emulsification no tau nruab nrog peb coaxial nplawm cov khoom sib xyaw, haum rau homogenization ruaj khov thiab emulsification, thiab cov emulsified hais tau me me heev. Qhov zoo ntawm emulsification mas nyob ntawm seb cov hais ua li cas tawg tau tawg nyob hauv kev npaj theem. Cov qhov nruab nrab me me, qhov qis dua qis dua yuav tsum sib sau ua ke rau ntawm qhov chaw, thiab yog li tsis muaj tsawg dua ntawm cov emulsification tau rhuav tshem. Relying ntawm kev sib xyaw ntawm thim rov qab, homogeneous turbine thiab lub tshuab nqus ua rau cov neeg ua haujlwm, zoo emulsification cov khoom sib cuam tshuam tau tau.

Kev ua haujlwm ntawm lub emulsification tank yog kom yaj ib lossis ntau cov ntaub ntawv (dej-soluble khoom theem, kua theem lossis jelly, thiab lwm yam) hauv lwm theem ua kua thiab hydrate nws mus rau hauv emulsion ruaj khov. Nws yog dav siv hauv emulsification thiab sib xyaw ntawm cov roj muaj peev xwm, hmoov, suab thaj thiab lwm yam ntaub ntawv nyoos thiab ntu. Cov emulsification thiab kev tawg ntawm qee yam txheej txheej xim thiab xim tsev kuj xav tau cov tso tsheb hlau luam emulsification. Nws yog qhov tshwj xeeb tshaj yog rau qee qhov tsis tseem ceeb colloidal ntxiv rau, xws li CMC, xanthan ntawm cov pos hniav, thiab lwm yam.

Thov

Lub tshuab emulsification yog qhov haum rau cov tshuaj pleev ib ce, tshuaj, khoom noj, chemistry, dyeing, luam ntawv kua mem thiab lwm yam lag luam. Nws yog qhov tshwj xeeb tshaj yog npaj rau kev npaj thiab emulsification ntawm cov ntaub ntawv nrog siab matrix viscosity thiab cov ntsiab lus muaj zog siab.

(1) Tshuaj pleev ib ce: cream, tshuaj pleev, di ncauj, tshuaj zawv plaub hau, thiab lwm yam.

(2) Tshuaj: tshuaj pleev, kua dej, tshuaj kho qhov muag, tshuaj tua kab mob ; thiab lwm yam

(3) Khoom noj khoom haus: jam, butter, margarine, thiab lwm yam.

(4) Tshuaj lom neeg: tshuaj lom neeg, tshuaj txhuam hluavtaws, thiab lwm yam.

(5) Cov khoom lag luam: cov xim muaj hlau, titanium oxide, thiab lwm yam.

(6) Kev luam ntawv number case: xim number case, ntxaij number case, ntawv xov xwm number case, lwm yam

Lwm tus: pigments, waxes, xim tsev, thiab lwm yam.

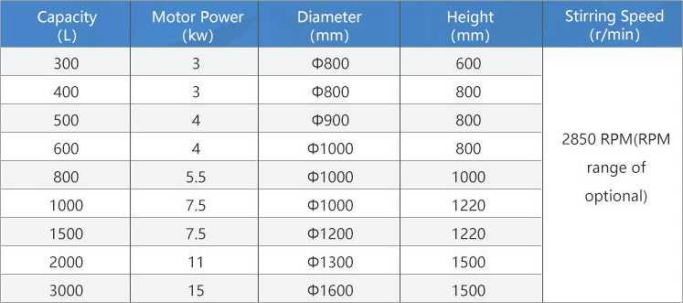

KHOOM SIV PARAMETERS

Kev them nyiaj yug cov ntaub ntawv: random muab cov khoom siv kos duab (CAD), teeb tsa kev teeb tsa, daim ntawv pov thawj khoom zoo, kev teeb tsa thiab kev qhia ua haujlwm, thiab lwm yam.

* Cov lus saum toj no yog rau kev siv xwb, tuaj yeem kho raws li tus neeg yuav tsum tau ua.

* cov khoom siv no tuaj yeem tsim kho raws li cov neeg siv khoom, yuav tsum ua raws li cov txheej txheem, xws li ua kom tau qhov siab viscosity, homogeneous muaj nuj nqi ntxiv dag zog, cov khoom kub-xws li qhov yuav tsum tau ua.

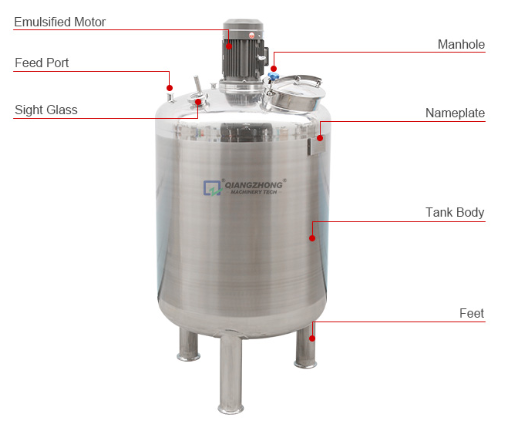

UA HAUJ LWM ZOO LICAS

Nws txoj hauv kev ua haujlwm yog tias lub zog centrifugal uas tsim los ntawm lub siab ceev thiab muaj zog tig rotor ntawm emulsifying lub taub hau cuam cov khoom rau hauv qhov nqaim thiab npliag ntawm qhov stator thiab lub rotor los ntawm kev taw qhia radial. Cov ntaub ntawv ib txhij raug rau centrifugal extrusion thiab kev cuam tshuam rau cov quab yuam kom tawg, sib xyaw thiab emulsified. Lub tank muaj qhov zoo ntawm tib neeg cov qauv, ntim tau ntim yooj yim, kev lag luam yooj yim, kev nyab xeeb thiab kev nyiam huv, thiab kev ua haujlwm ruaj khov. Nws koom nrog kev siab ceev shearing, dispersion, homogenization thiab sib xyaw.