Cov non-txheem kev cai sib xyaw tank

Txhawm rau ua hmoov los yog muab tshuaj ntxiv, ua kom sib xyaw cov khoom sib txawv. Yog kab tav toj tav toj ib oar sib tov sib xyaw? impeller rau ncej, yooj yim los ntxuav.

Khoom Taw qhia

No cov cuab yeej ua tiav raws li lub teb chaws "tshuaj ntau lawm kev tswj cov qauv zoo" GMP "yuav tsum muaj cov khoom siv; Thiab nias rau "steel welding atmospheric txog ntsha" (JB / 4735-1997), thiab lwm yam qauv tsim, tsim khoom, tsim nyog rau thaj chaw huv kev lag luam kws tshuaj, kev lag luam khoom noj, kev npaj ua kua ntawm kev ua txhaum (cov khoom lag luam) cov txheej txheem thiab txhua yam kev kho dej cov txheej txheem, tib lub sijhawm los ua tus qauv, ua txhua yam tsis muaj cov thawv ntim cim. 1, cov khoom siv yog 316 Kuv lossis 304, kev kho polishing nyob rau saum npoo, qhov saum npoo roughness Ra0.4 microns. 2, nplawm rau sab saum toj thiab hauv qab cov khoom siv nplawm: sab saum toj cov khoom sib xyaw ua ke yog: lub voom vias, ntsia hlau, thauj tog rau nkoj, kos cov taub hau lossis kos taub tov khoom, thiab lwm yam.; Muab cov khoom sib tov. Do hauv daim rau hauv qab ntawm daim ntawv yog: sib nqus sib nqus, sib nqus sib xyaw, muaj qab hauv siab shear emulsification taub hau; Kev nrawm nrawm rhuav tshem cov khoom thiab emulsion. Kev sib tov sib xyaw nrog kev xaiv sib xyaw nrog kev ceev ceev lossis kev tswj hwm ntawm lub cev muaj zog ceev, kev tswj hwm tus nplawm nrawm yuav zam dhau lub nrawm dua thiab tsim npuas. Cov nplais ntawm cov hlau tsis huv hluav taws xob tswj lub txee tuaj yeem ua tiav cov cuab yeej ua haujlwm, thiab nws tuaj yeem tso saib ntsuas kub, nplawm qhov nrawm thiab lwm yam ntaub ntawv. 3, kev teeb tsa yog: lub tshuab pa ntsuas cua, ntsuas qhov cub, lub qhov ncauj kom tsis muaj menyuam, kev noj qab haus huv mus rau hauv lub qhov, qib thiab kua theem tswj kev tswj hwm, kev sib hloov thoob ntiaj teb ua kom huv si lub pob lossis teeb tsa raws li cov neeg siv khoom. 4, lub tsho hnav khaub ncaws tuaj yeem ua raws li cov neeg siv khoom, coil thiab tag nrho lub tsho, ua tsho khuam muaj sia. 5, rwb thaiv tsev raws li cov neeg yuav tsum tau ua, siv pob zeb tsiaj: polyurethane ua npuas dej, hlaws paj rwb npauj, lub plhaub tuaj yeem ua raws li tus neeg siv yuav tsum tau ua polishing thiab kos duab lossis ua haujlwm qis dua. 6, cov ntsiab lus tshwj xeeb: 301 - 30000 I.

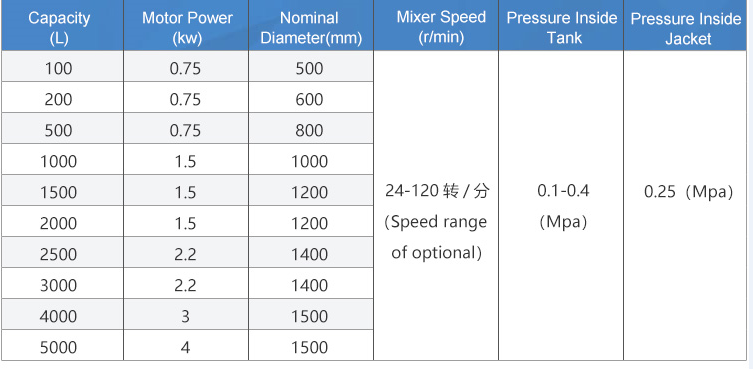

Gl Khoom muag PARAMETERS

Kev them nyiaj yug cov ntaub ntawv: random muab cov khoom siv kos duab (CAD), teeb tsa kev teeb tsa, daim ntawv pov thawj khoom zoo, kev teeb tsa thiab kev qhia ua haujlwm, thiab lwm yam.

• Agitation tank los ntawm kev sib xyaw cov roj tank, sib xyaw tank npog, sib xyaw, kev coj tus kheej, ua haujlwm, cov iav, cov khoom siv sib khi, thiab lwm yam.

• Lub tshuab sib tov, kev sib tov cov roj tank, sib xyaw tank npog kom xaiv cov khoom siv xws li cov npoo av tuaj yeem xaiv tau raws li kev sib txawv ntawm cov pa roj carbon steel lossis steel hlau thiab lwm yam khoom siv los tsim.

• Kev sib xyaw ua ke tank thiab tank npog flange foob sib txuas lossis vuam sib txuas tau siv tau. Kev sib xyaw cov roj tank thiab cov npog npog raws li kev siv thev naus laus zis rau kev pub mis thiab tawm, kev soj ntsuam, ntsuas kub, pa taws, tawg pa luam yeeb, kev nyab xeeb lub qhov quav yeeb lub qhov txheej txheem

• Nruas los npog cov txheej txheem sab saud tau muaj cov khoom siv sib kis (lub cev muaj zog thiab lub tshuab txo qis), tsav los ntawm lub zog tsav sib tov sib xyaw cov roj tank.

• Lub tshuab kaw khawm tuaj yeem siv tshuab los ntim khoom lossis ntim khoom, ntau hom qauv xws li lub labyrinth foob (raws li tus neeg siv yuav tsum tau txiav txim siab).

• Raws li cov neeg siv xav tau cov txheej txheem sib txawv, cov tshuab sib xyaw ua ke plasma hom, thauj tog rau nkoj, thav duab hom, kauv, thiab lwm daim ntawv.

• Cov khoom hu rau ntu yog hlau xeb SUS304 lossis 316 ua rau peb cov khoom ua tau raws li qhov xav tau ntawm GMP.

KHOOM KHWV