GJ UA HAUJ LWM COV LUS QHIA

Sib xyaw ua ke sib xyaw, emulsification, homogenization, xaus, rhuav thiab lwm yam Ua kom zoo dua emulsification efficiency, txuag lub sijhawm sib tov thiab txo cov pov tseg ntawm cov khoom nyoos

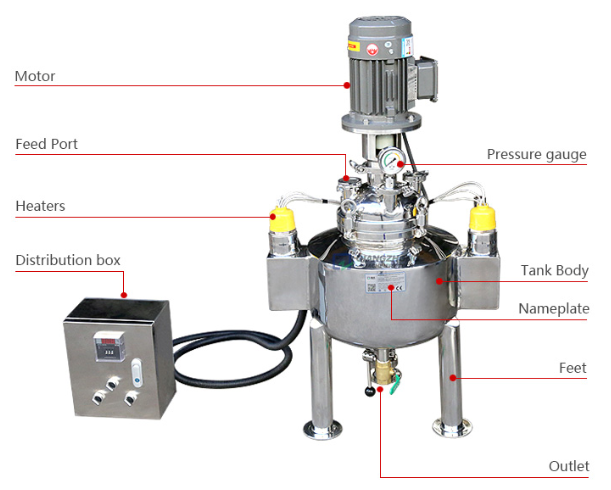

Khoom taw qhia

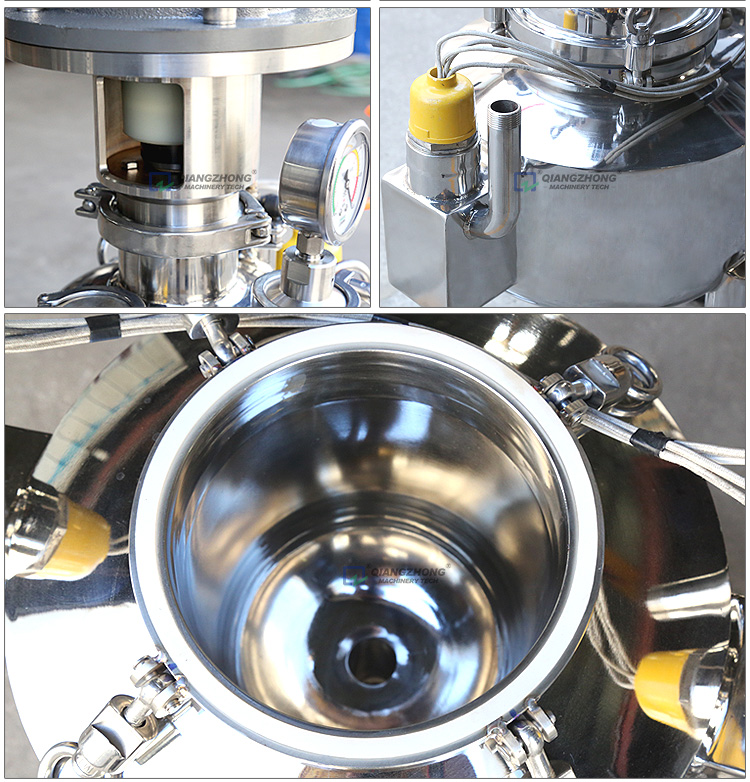

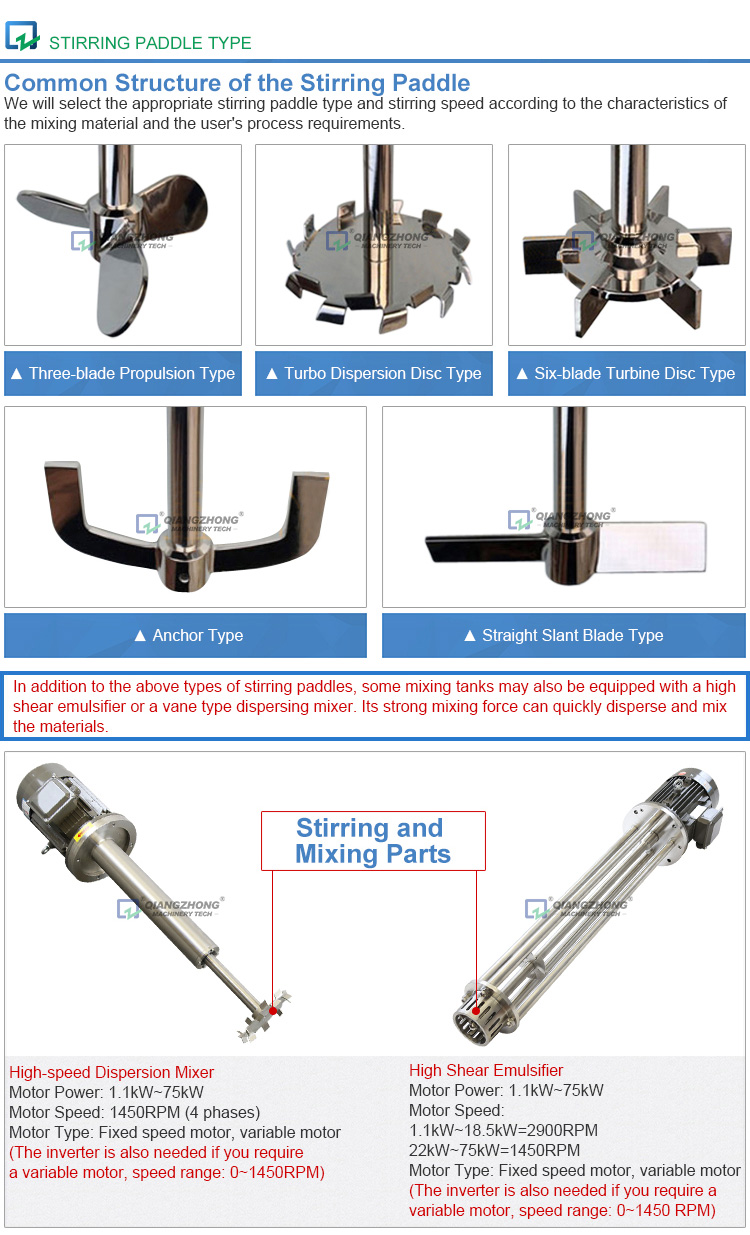

Cov khoom siv tuaj yeem paub txog cov txheej txheem ntawm cov khoom tawg, emulsification, homogenization thiab sib xyaw hauv qab nqus lossis siab ib puag ncig. Nws muaj cov homogeneous tov khoom, nruab nrab hniav sib xyaw thiab phab ntsa scraping tov khoom. Lawv txhua tus nyias muaj nyias tus yam ntxwv, sib xyaw ua ke, thiab sib xyaw los ua cov txheej txheem sib tov zoo tshaj plaws, uas tuaj yeem sib xyaw cov khoom siv los tsim cov khoom lag luam zoo nrog cov lus nplua nuj, zoo nkauj thiab ductility zoo. Kev ua haujlwm ntawm lub emulsification tank yog kom yaj ib lossis ntau cov ntaub ntawv (dej-soluble khoom theem, kua theem lossis jelly, thiab lwm yam) hauv lwm theem ua kua thiab hydrate nws mus rau hauv emulsion ruaj khov. Hauv tshwj xeeb, nws muaj cov roj zoo zom thiab emulsifying ua rau cov piam thaj, mis hmoov, thiab cov pos hniav ntxiv rau hauv ntau lawm, thiab tam sim no nws yog qhov ua tau zoo tshaj plaws ntawm cov khoom lag luam zoo sib xws. Tab sis qee zaum rau cov khoom siv sib txawv thiab kev ua haujlwm, ib lub tshuab emulsifying hauv lub emulsifying tank feem ntau tsis tuaj yeem ua tau raws li kev tsim khoom. Nyob rau lub sijhawm no, nws yuav tsum tau nruab nrog lwm tus neeg ua kom pab txhawm rau txhawm rau txhawm rau kom qhov sib xyaw ua kom tiav zoo dua.

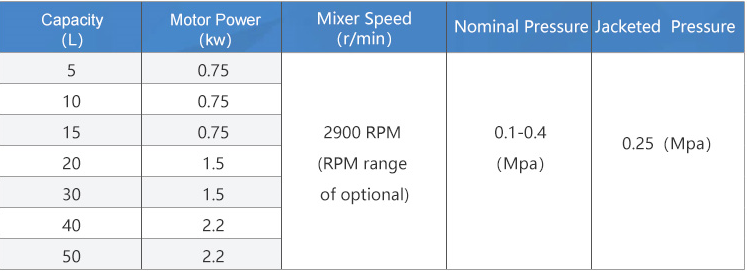

GJ TXOJ KEV PARAMETERS

Kev them nyiaj yug cov ntaub ntawv: random muab cov khoom siv kos duab (CAD), teeb tsa kev teeb tsa, daim ntawv pov thawj khoom zoo, kev teeb tsa thiab kev qhia ua haujlwm, thiab lwm yam.